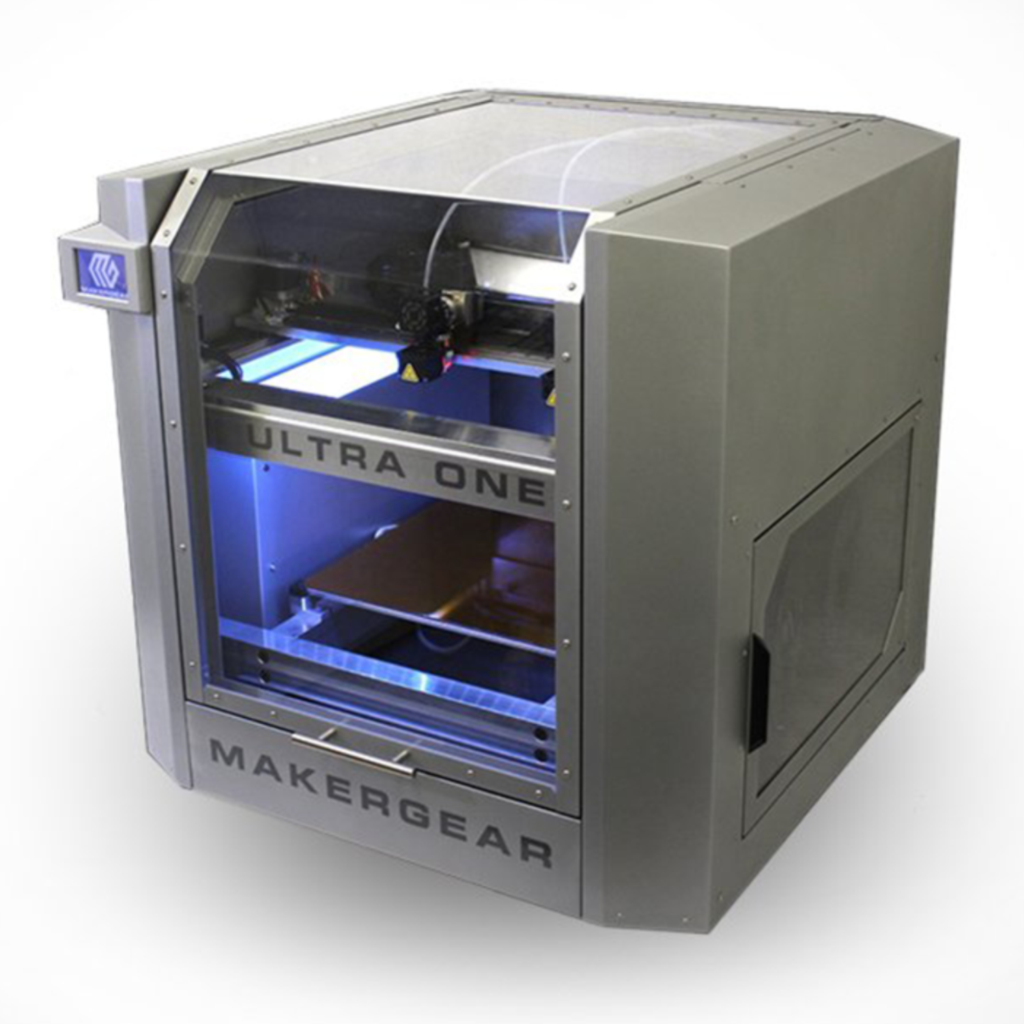

RTD has invested in a Makergear Ultra One 3D printer. It is capable of printing 16“ wide x 14” deep x 13” high utilizing independent dual extruders. A high-temperature capability enables RTD to print a wide variety of materials such as nylon, polycarbonate, polypropylene, and more.

RTD offers solid modeling services as a way to quickly create your prototype while also keeping costs low. Traditional manufacturing requires multiple different operations to produce a prototype, and not one operation can be missed. These stages relied heavily on digital models and these with limitations. This process tends to be more expensive and time-consuming making 3D printing the better option. With 3D printing, designing the prototype, and uploading it to our 3D printer is all that’s required.

The last advantage of 3D printing is that it only uses the required material to create a part which means minimal waste and very little labor. Standard processes machine material away leaving scrap metal as a result. 3D printing is an additive machine meaning the only material that will be used will be the material that makes up the prototype.

Looking to 3D print your next prototype? Click on the button below to submit your RFQ.