The success of Reich Tool & Design has been built on the foundation of supplying quality systems, components and tools to our diverse customer base. The strength of this foundation comes from the people and the quality systems that have been put in place to ensure the strictest of requirements are not only met but exceeded.

ISO 9001:2015 Certified by NQA

ISO 13485:2016 Certified by NQA

ISO Class 7 per 14644-1 Certified by Class 1 Air

AS 9100 Compliant

We are proud of our certifications and take serious the commitment to supporting and maintaining these quality systems. We approach every phase of the order and production process keeping in mind, the end result of providing the highest quality product we are capable of producing.

Our facility is equipped with current technologies available to qualify the conformity of a product before it is received at our customer’s point of use.

The technology driving the department is the backbone that supports our systems:

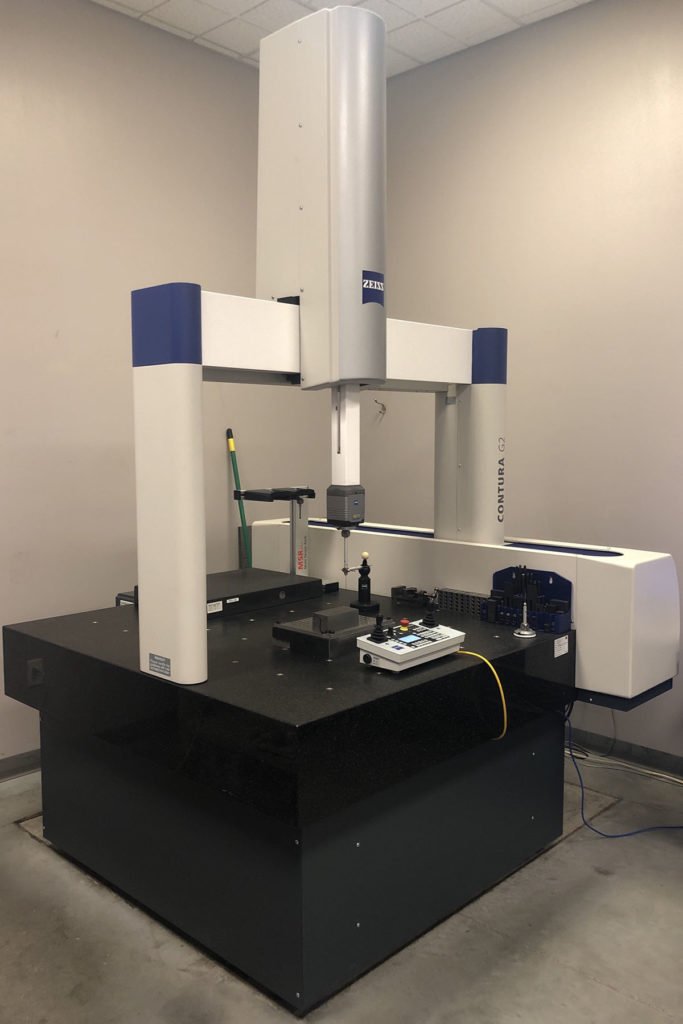

Zeiss CMM

- Calypso Software

- 39” x 47” x 23.5” Measuring Envelope

- Aktiv Scanning Technology

FARO Arm

- Polyworks IM Inspect Software

- Laser Scanner

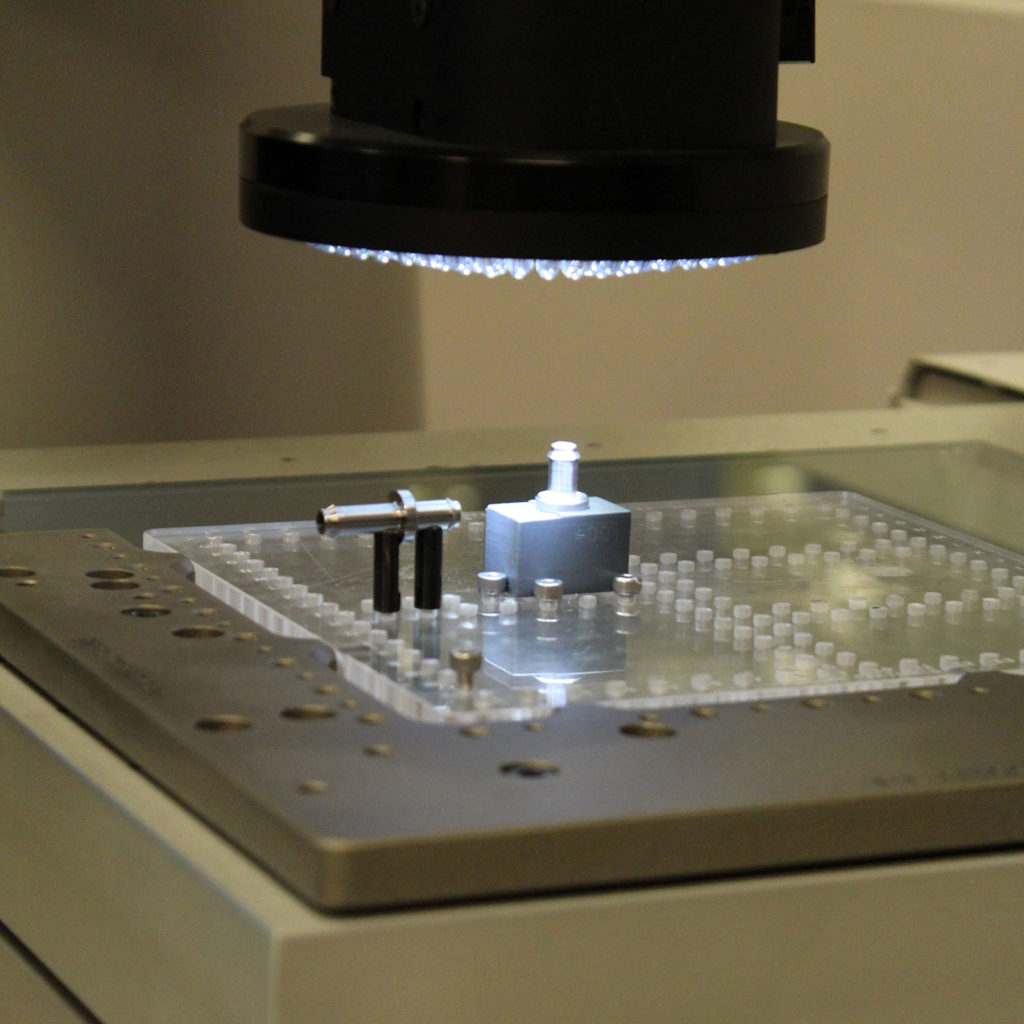

Micro Vu Vision System

- 12 X 12 X 6 Measuring Area

- 272 Power Digital Zoom

- 816 Power Optical Zoom

The investment we’ve made in the latest technologies for this department assist in our being able to support our customers ever-increasing requirements for quality. These tools along with PPAP, APQP, and FEMA support our continuous improvement efforts and our commitment to our customers.

When you have a product that you do not have a drawing for, you can count on our quality and engineering departments to work together to reverse engineer your part. By scanning the components with our laser we are able to create a fully dimensioned model and subsequent drawings.