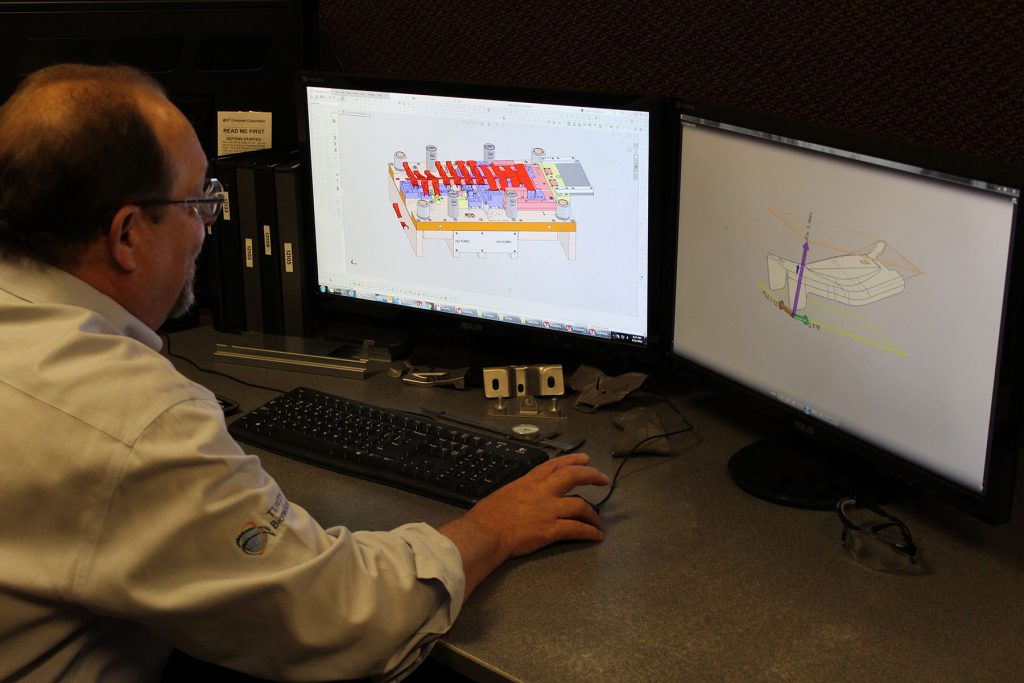

The foundation for creating superior stamping dies begins with the development of a tool that is designed to produce parts with maximum productivity. Our team of design & engineering professionals is highly proficient craftsmen that have been trained in advanced techniques to create the best tool designs for our customer’s application.

To enhance the skills of our design & engineering team we have incorporated the latest in Solidworks and Logo Press software to assist in the development, modeling, and layout process to ensure the forming simulations will be achievable in the die as designed.

RTD accepts all the standard file formats:

- STP

- Parasolid

- IGES

- AutoCad

- Solidworks

Our design & engineering software is driven by latest technology water-cooled computers allowing them to process more data at higher speeds than conventional systems permit.

No die design would be complete without the inclusion of input from our valued customers. Customer contribution is key in all phases of the tooling process from concept to strip layout to first piece production.

Our experienced design staff can assist with reverse engineering on parts for projects where you may have a sample and no drawing or poor drawings to work from. The software utilized in our quality lab allows for us to create a drawing by performing a detailed scan which can be converted to a fully dimensioned model.