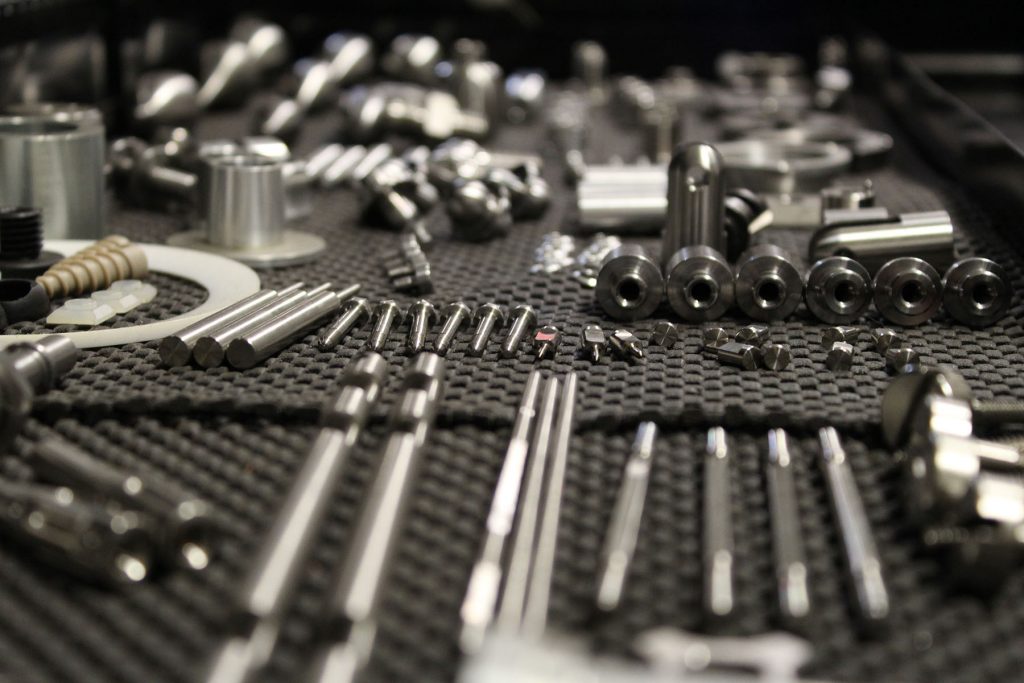

To meet the demands of our customers and their ever-changing needs, Reich Tool & Design has enhanced our production capabilities to include high-performance CNC Turning & CNC Swiss Machining services.

We bring a new level of attention and accuracy to the production of small parts & those with complex geometries, and long, slender characteristics.

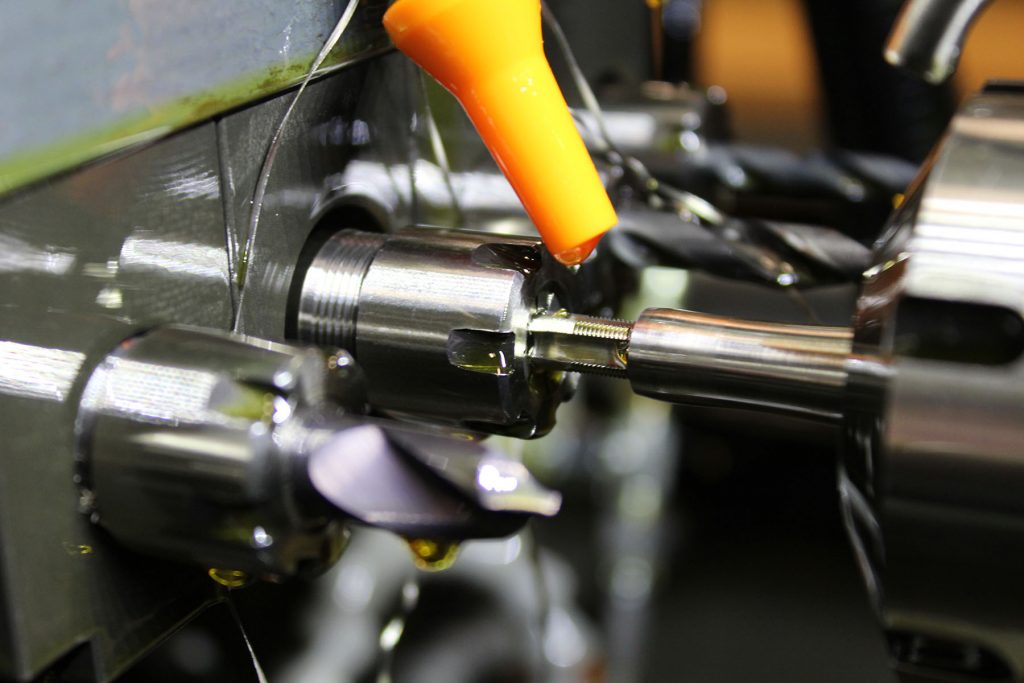

Our Tornos Swiss-type turning center, with Live Tooling, attributes seven linear Axes, plus two “C” Axes, as well as a modular tooling setup, providing a variety of complex operations to be performed concurrently.

“We always look to Reich Tool first for our turning work that exceeds our shop capacity and I would not hesitate to send others to them if the parts are beyond our shops capacity threshold.”

S.L., Sales Manager

Metal Industry

We have the ability to machine parts as small as .060” in diameter and .060” in length. Equipped with a 12-foot bar feed system that allows us to feed material up to 1” in diameter.

- CNC Swiss Turning

- 7 Linear Axis

- 2 “C” Axes

- 1” Diameter Capacity Bar Feed

- Small Complex Parts

RTD’s CNC Turning capabilities include the ability to turn parts up to 15.30” in diameter and 19” in length.

Mazak turning center, with Live Tooling, excels in machining parts up to 3” diameter with remarkable throughput at a high level of productivity due to the Automated Bar Feed process.

- 15.30” Diameter

- 19” Maximum Length

- Live Tooling

- Bar Feed up to 3” Diameter

In most cases, secondary operations are eliminated since we can mill, drill, ream, saw, do deep boring, and internal & external thread whirling, all within these machines.

We execute progressive solutions for producing close tolerance parts with superb finishes and shorter lead times.

Working in virtually all materials:

- Carbon Steel

- Stainless Steel

- Aluminum

- Titanium

- Copper Alloys

- Aircraft Alloys

- Plastics & Phenolic

No matter the size of your order, from prototypes to high volume production runs, your small diameter, tight tolerance and geometrically complex parts will be produced to your specification every time, quickly and affordably.