RTD provides high-value manufacturing concepts to a wide variety of demanding industries with our advanced CNC machining capabilities.

We have strategically invested in state of the art, high-speed CNC machines to consistently hold tight tolerances and process parts to an increased level of precision and productivity.

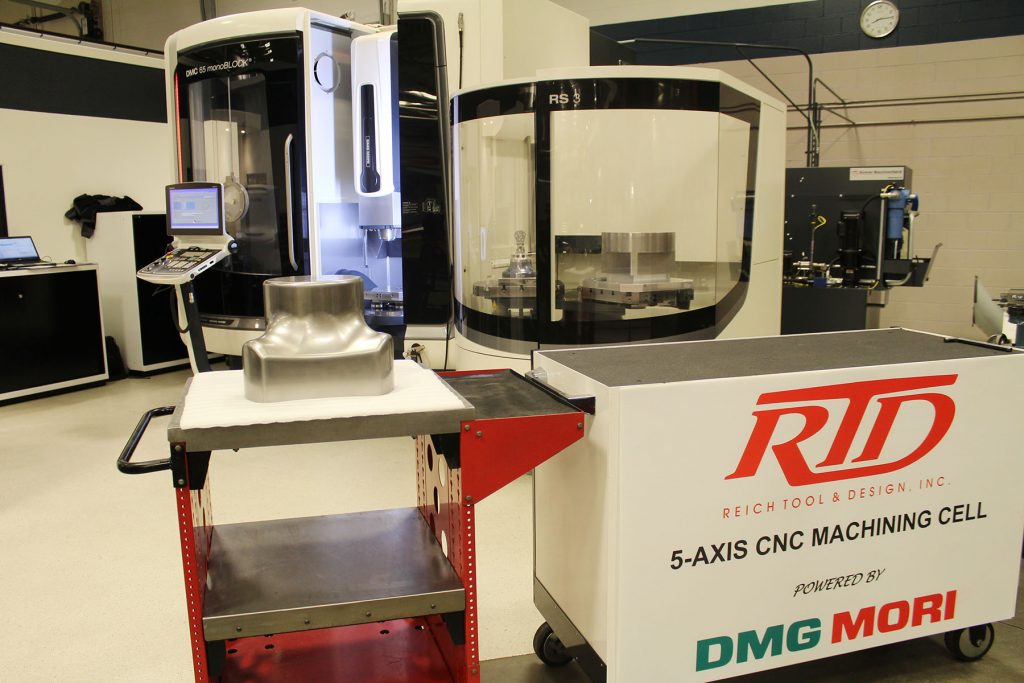

Recently, we have invested in a powerful 5-Axis DMC 65 MonoBlock® Machining Center, equipped with an automatic pallet changer for absolute efficiency and maximum production.

“Reich Tool has been a long-time supplier and customer. The wide range of machining and waterjet capabilities keep them in the front of my mind for nearly any type of job that comes our way. We appreciate all of the business that comes our way, in addition to the personalities that are represented when communicating. We look forward to many more years of what is a great partnership.”

C.F., President

Heavy Truck Industry

We can promote high-speed production of complex parts with a lot of flexibility due to the swivel rotary table, 90-tool capacity, and spindle speeds of up to 18,000 RPM. The 5-Axis has a large work area, allowing sizes up to 24.8” X 19.7” to be 3D machined using 3+2 or true 5-Axis cutting.

- DMG Mori 5-Axis

- 90 Tool Capacity

- 3 Pallet Changer

- 18,000 RPM

- 24.8″ X 19.7″ Work Envelope

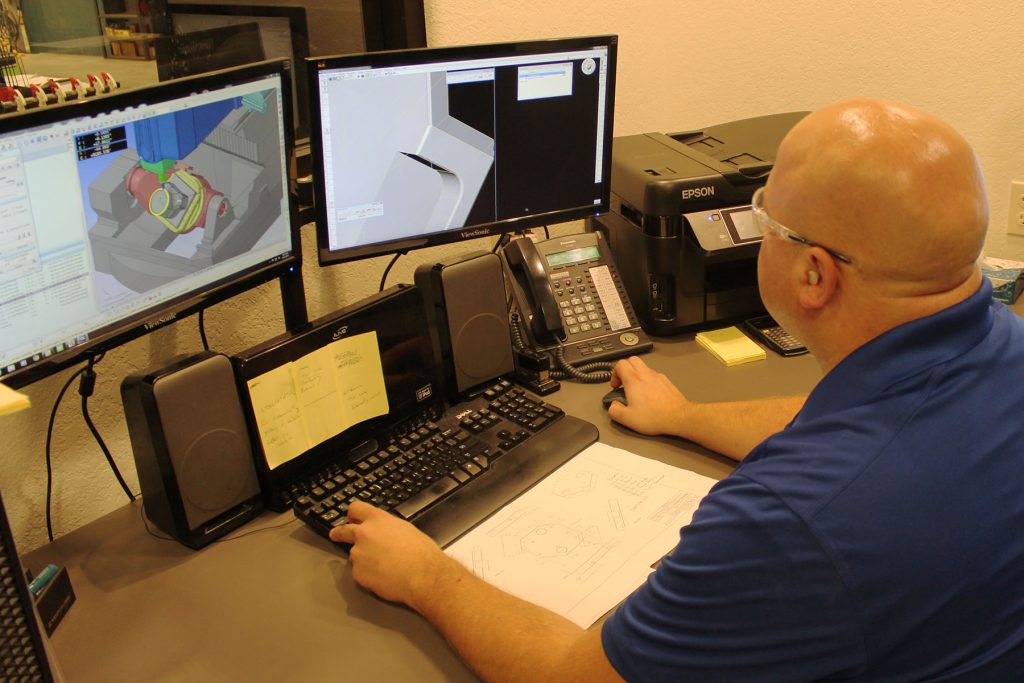

We house multiple CNC Machining centers, and have a team of skilled, knowledgeable CNC specialists with the experience to complete projects on time, at the highest level of quality. Our leading-edge software that is used to program tool paths can trim cutting times by up to 50%. With our custom-designed set-up pallet system, parts flow through the machining process rapidly & systematically, allowing us to achieve the greatest efficiency of each machine.

These machining centers are superb at cutting a multiplex of shapes, drilling holes at complicated angles, and achieve exemplary surface finishes which ultimately saves steps by reducing the man hours needed to generate parts. It allows better access to intricate part geometry, making the “Print to Part” process much faster to help improve productivity and profitability.

With spindle speeds up to 20,000 RPM and 1,000 psi thru-spindle coolant system, our 3-Axis machines are able to drill up to 7 times faster than typical high-speed drilling processes. We CNC machine simple shapes or geometrically complex parts with dimensions up to 116” in length X 50” in width X 36” in height.

- 3-Axis Machining

- 20,000 RPM Spindle Speeds

- 1,000 PSI Thru-Spindle Coolant

- Maximum 116” x 50” x 36” Capacity

- Shrink Fit Tooling

Our CNC’s have the power to machine materials such as Aluminum, Copper, Titanium, Stainless Steel, Nickel, Carbon Steels, Alloy and Tool Steels. We also have the specialized skills to machine high-strength, high-temperature Aerospace Super Alloys.

Whether it’s a high volume order, or a 1 piece prototype project, we can supply it to your precise requirements, every time.