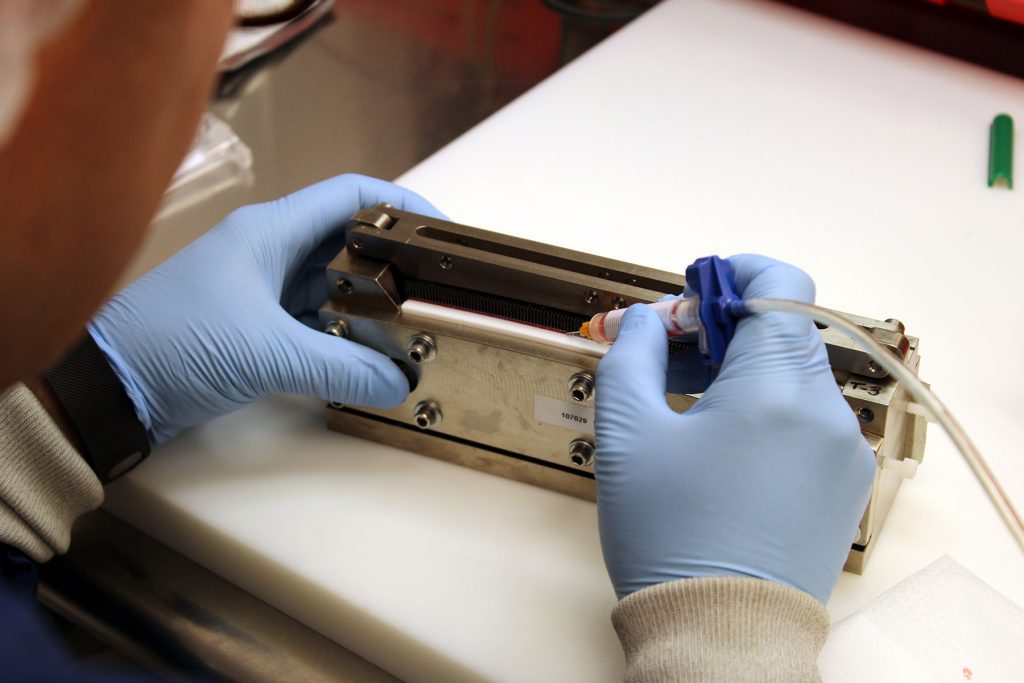

As a fully equipped solutions provider, RTD utilizes our sister company, Trinity Precision Solutions (TPS), to provide assembly services within our Class 10,000 cleanroom. We are ISO 9001:2015 Certified by NQA and ISO 13485:2016 Certified by NQA, and build custom assemblies that display a high level of quality and comply with all relevant regulatory requirements.

TPS is located within the RTD Campus and offers a variety of mechanical assembly capabilities, including Adhesive Assembly, Snap-Fit Assembly, and Micro Welding. We have the knowledge and expertise, across a vast range of bio- and contamination-sensitive products that vary in size and complexity.

Our cleanroom assembly specialists have an exemplary mix of skills to support a broad range of product assembly needs. We have advanced adhesive equipment to be able to assemble customer products per their design and tolerances.

With our cleanroom measuring & test capabilities, we affirm that the assembled products will conform exactly to your specifications, and all components are pre-treated to assure the highest degree of purity prior to assembly.

- ISO Class 7 (Class 10,000) Cleanroom Certified by Class 1 Air

- ISO 9001:2015 Certified by NQA

- ISO 13485:2016 Certified by NQA

To support our cleanroom, we promote a variety of mechanical test equipment to verify the quality of your assembled products including two CMM’s that take highly detailed 3D measurements; high-end laser scanning and automated vision systems for Inspection and CAD comparison.

We develop, test and package crucial products for industries such as medical, aerospace, food processing, military and many more.

You can utilize our custom cleanroom assembly solutions for 1 piece prototypes, as well as those with production quantities.