Housed within the RTD Campus, our sister company, Trinity Precision Solutions (TPS) applies their technical knowledge of Ultrasonics and Ultrasonic technology to lead the way for Multi-Sonic Washing within our facility.

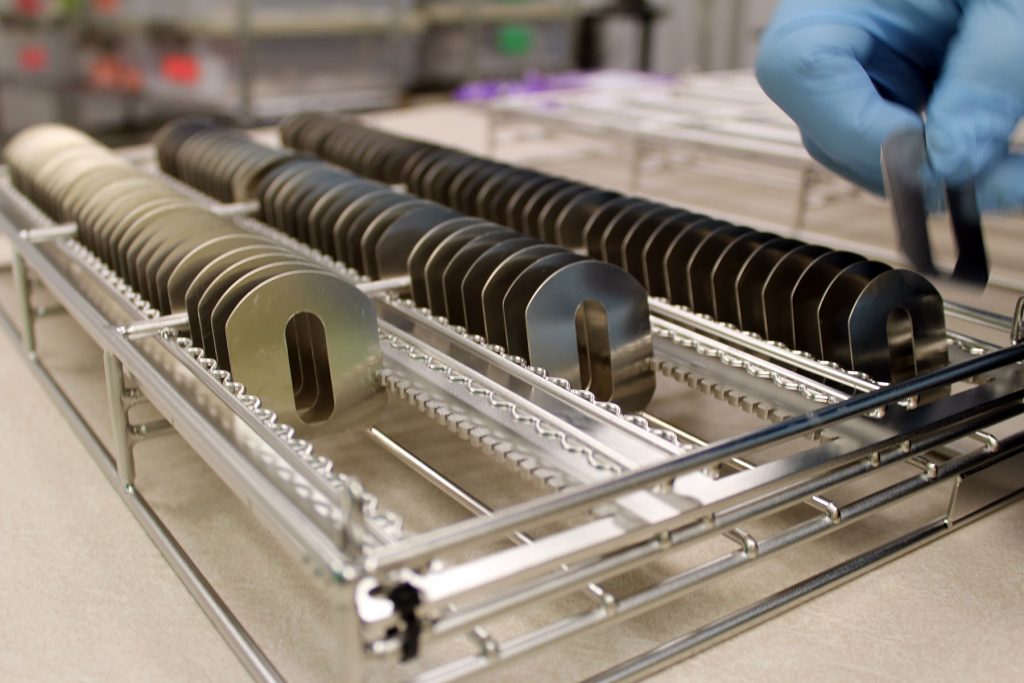

Cleaning Critical Components:

Our process is adapted for the cleaning of complex components in a variety of shapes and sizes, composed from almost any material and those processes produce minimal residue results that will surmount your cleanliness expectations.

Industries Served by Ultra-Sonic Washing:

- Medical

- Aerospace

- Fluid Power

- Automotive

- Electronic

Ultrasonic cleaning uses high-frequency sound waves to create cavitation bubbles in a cleaning solution, which contains high-purity, de-ionized water, with or without chemicals or detergents, approved by our customers.

As the Ultrasonic energy permeates deep into cavities and crevices, it productively cleans parts with intricate internal details, physically loosening and removing surface contamination on a microscopic level.

We operate advanced Ultrasonic washers that produce multiple frequencies to achieve the ultimate level of part cleanliness, removing tough contaminants, not harming the substrate in any way and reaching the highest level of cleanliness based on the part material and geometry.

Using high-purity, de-ionized water, which is the newest technology in reverse osmosis water purification systems, it effectively absorbs contaminants. It also actively removes all trace amounts of cleaning solution left on the part, when used as a second-stage rinsing agent, making it an integral part of our ultrasonic cleaning procedure.

Let us show you that with our skill and experience, we can provide the best and most effective ultrasonic cleaning solutions for your needs.